POP

Point of Production

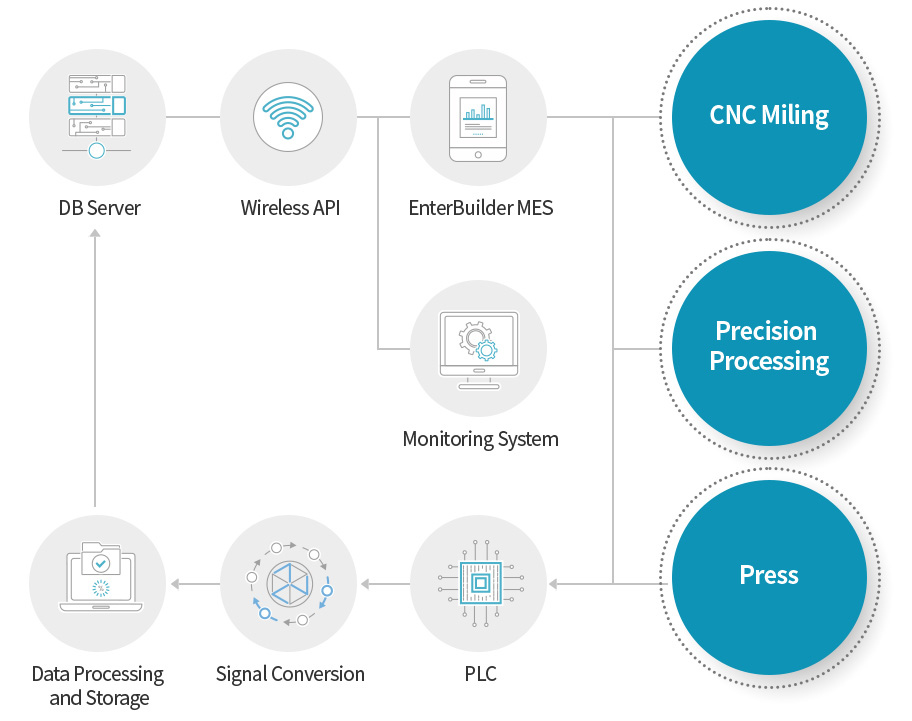

POP is point-of-production management, meaning real-time processing of information occurring in production, but in some areas the boundary with MES is not clear. EnterBuilder decides to define POP as the part that connects to production equipment, receives signals from production equipment, processes them in real time, and reflects them in management. EnterBuilder is provided for use in management by connecting various signals provided by the following production facilities.

1. Production quantity information: Automatically calculate production volume by linking production quantity information from production facilities.

2. Operation time information: Automatic calculation of operation time by obtaining facility operation time.

3. Heating temperature: Obtain the heating temperature value and apply it as quality information.

4. Input information: Acquire input information and apply it as quality information.

5. Measurement information: Obtain the measured values of the automatic measuring device and apply them as inspection values.

Purpose of introduction

Acquisition of mechanical information without error

The mechanical information generated by the operation of the facility produces little error compared to the information processed by humans. Information processed by humans is likely to fail at the time of processing or the values processed by the facility, but the values processed by the facility can obtain accurate values at the correct time, resulting in much higher reliability values.

Acquisition of unprocessable information

In many cases, it is impossible for a person to process the values of a fast-moving facility or an inaccessible part, but obtaining the values provided by the facility is not a problem at all.

Acquisition of uninterrupted information

In the case of humans, data is processed only during working hours, but in the case of machines, information can be processed automatically throughout operating hours. As a result, there is no disconnection in processing information.

Acquisition of real-time information

It is impossible for a person to continue to counter the amount of production a machine works to process data, but just as a real-time counter can be obtained by connecting a counter by a facility to data, it has the advantage of being able to obtain all the information provided by the facility in real time.

Utilization of POP information

It is used for various purposes depending on the type of facility and the purpose of using the acquired data, but it is often used for production management, uptime management, and quality data management. EnterBuilder provides appropriate POP systems for production facilities and management purposes.